Deep Foundations

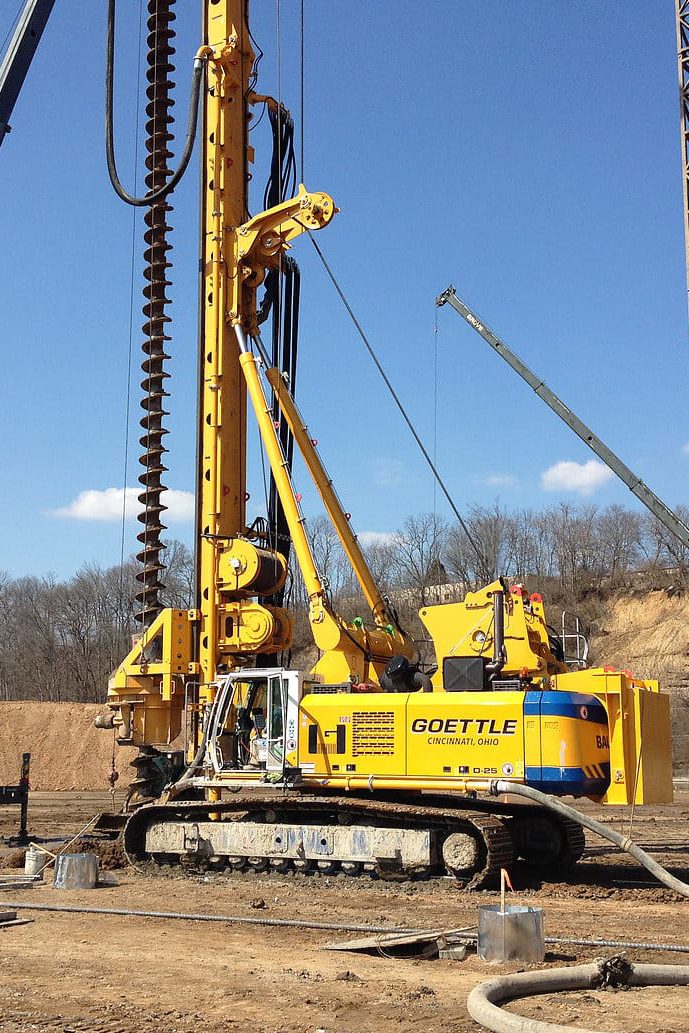

When structural loads exceed what a standard shallow foundation can carry, deep foundations are designed to transfer the load using friction or end bearing resistance. Many factors, including structural loads, soil conditions, and access to the work area, should be considered when choosing the right deep foundation system for your project. Goettle specializes in the installation and design of various deep foundation systems, including drilled shafts, augercast piles, micropiles and driven piles. Contact us today for assistance with choosing the right deep foundation system for your project.

Augercast piles are smaller diameter, cast-in-place deep foundation elements. They can vary in diameter from 12 to 48 inches and are most efficient in granular or incohesive soil and/or high water tables. Augercast piles can be installed quickly with minimal disturbance in noise and vibration. They can be designed as end-bearing, friction or a combination of both depending on the soil properties and proximity to rock.

Augercast piles are installed by rotating a hollow stem, continuous flight auger into the earth to the designed depth. Structural grout is then pumped through the hollow stem as the auger is slowly withdrawn. Once the hole is pumped full of grout, reinforcement can be placed.

Driven piles are a deep foundation element that is a pre-manufactured structural shape and can provide a wide range of capacities. There are a variety of driven pile types, including h-piles and pipe piles. Driven piles provide excellent quality control because they can be physically inspected prior to installation and during installation. Driven piles are installed using an impact or vibratory hammer.

Drilled Shafts, also known as caissons, are high capacity, cast-in-place deep foundation elements. They can vary in diameter from 24 to 144 inches and can be installed in a wide range of soil and rock conditions.

Drilled Shafts are installed by advancing an auger / drill tool to the required depth using open hole, casing or slurry techniques. Once the desired tip elevation has been achieved, the drilled shaft reinforcement is sent in place and the drilled shaft is filled with concrete.

Micropiles, also known as pin piles or minipiles, are small diameter, high capacity deep foundation elements. They can vary in diameter from 4 to 10 inches. Due to its minimal disturbance and small installation footprint they can be designed for both new construction and for existing structures.

Micropiles are installed by advancing a casing through the overburden material by flushing the cuttings with the aid of water or air. If applicable, once the casing has been advanced to rock, the designed rock socked is excavated utilizing a down-the-hole hammer. Once the excavation is complete, the reinforcing bar is placed and cement grout is pumped.

A drop shaft is an underground vertical or inclined passageway. Drop shafts are constructed for a number of reasons, including the ventilation of a tunnel or underground structure, as a drop shaft for a sewerage or a water/service tunnel or for access to a tunnel or underground structure, which can also be used as an escape route.

Shafts can be sunk either dry, or for methods such as the caisson method, they can be sunk using a slurry method.